Material engineering

Material testing

We analyse materials and perform routine tests on components and assemblies, which include testing and analysing a range of properties.

- Testing specific material properties

- Tensile, pressure and hardness tests

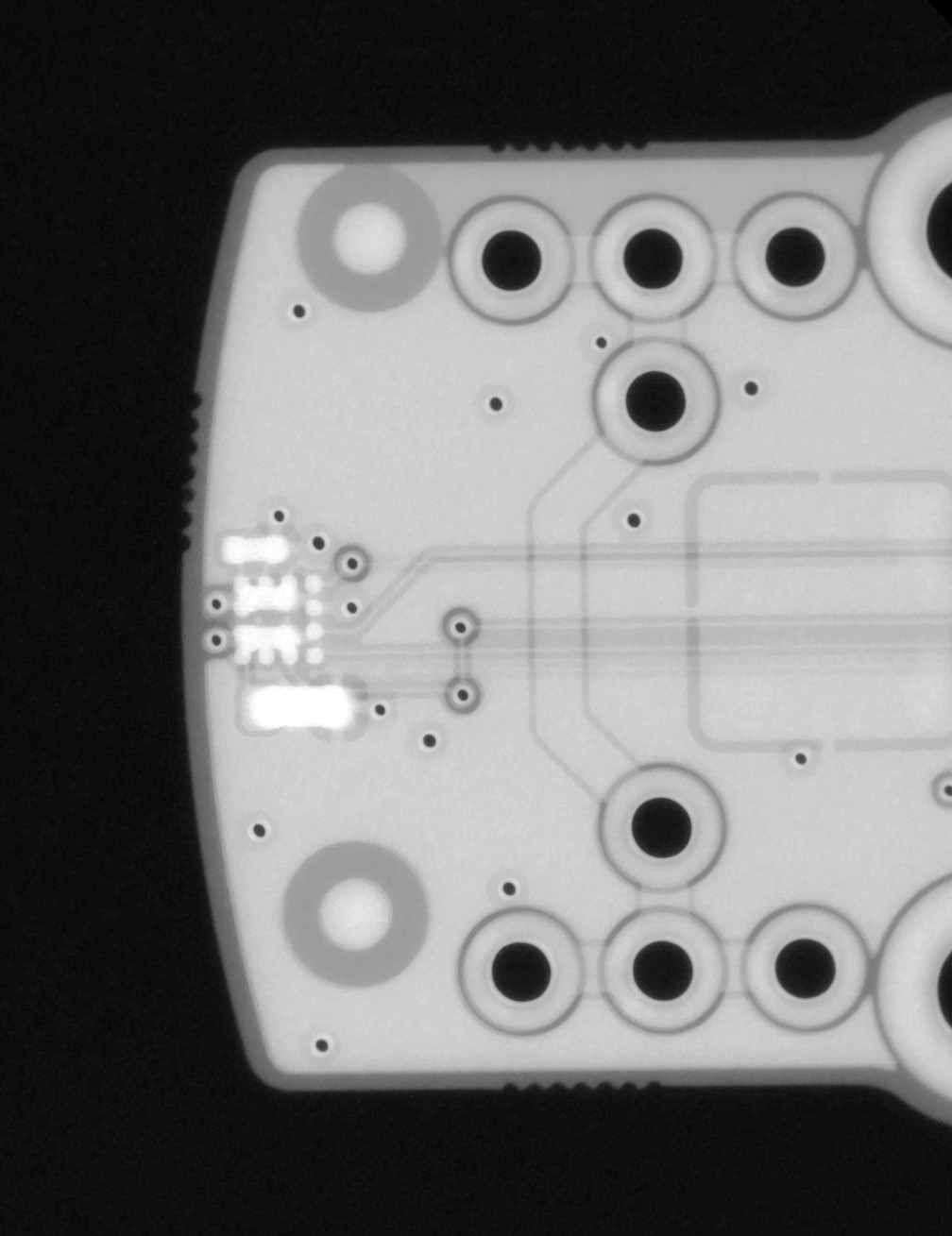

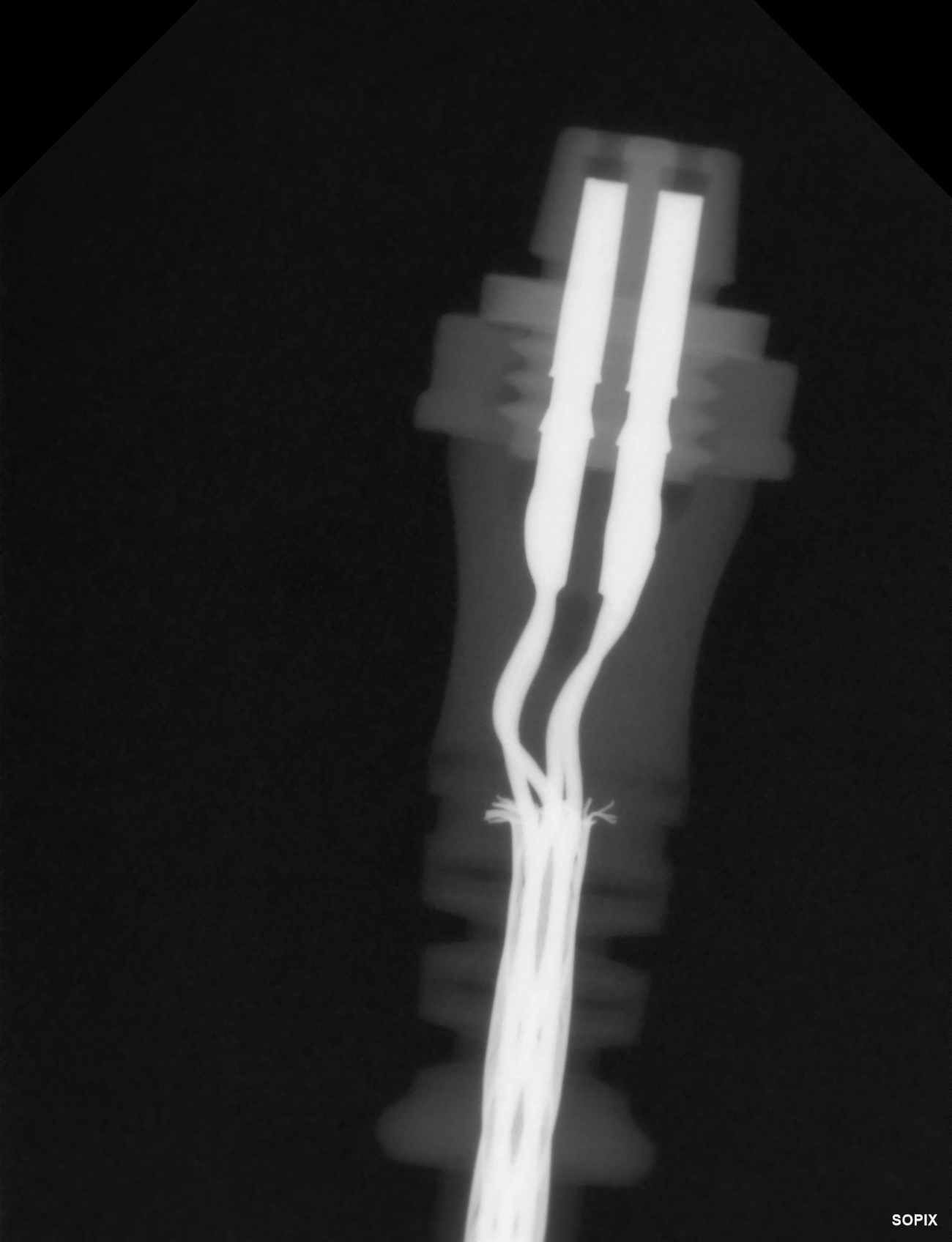

- Part, component and device failure analysesX-ray analyses (digital sensor)

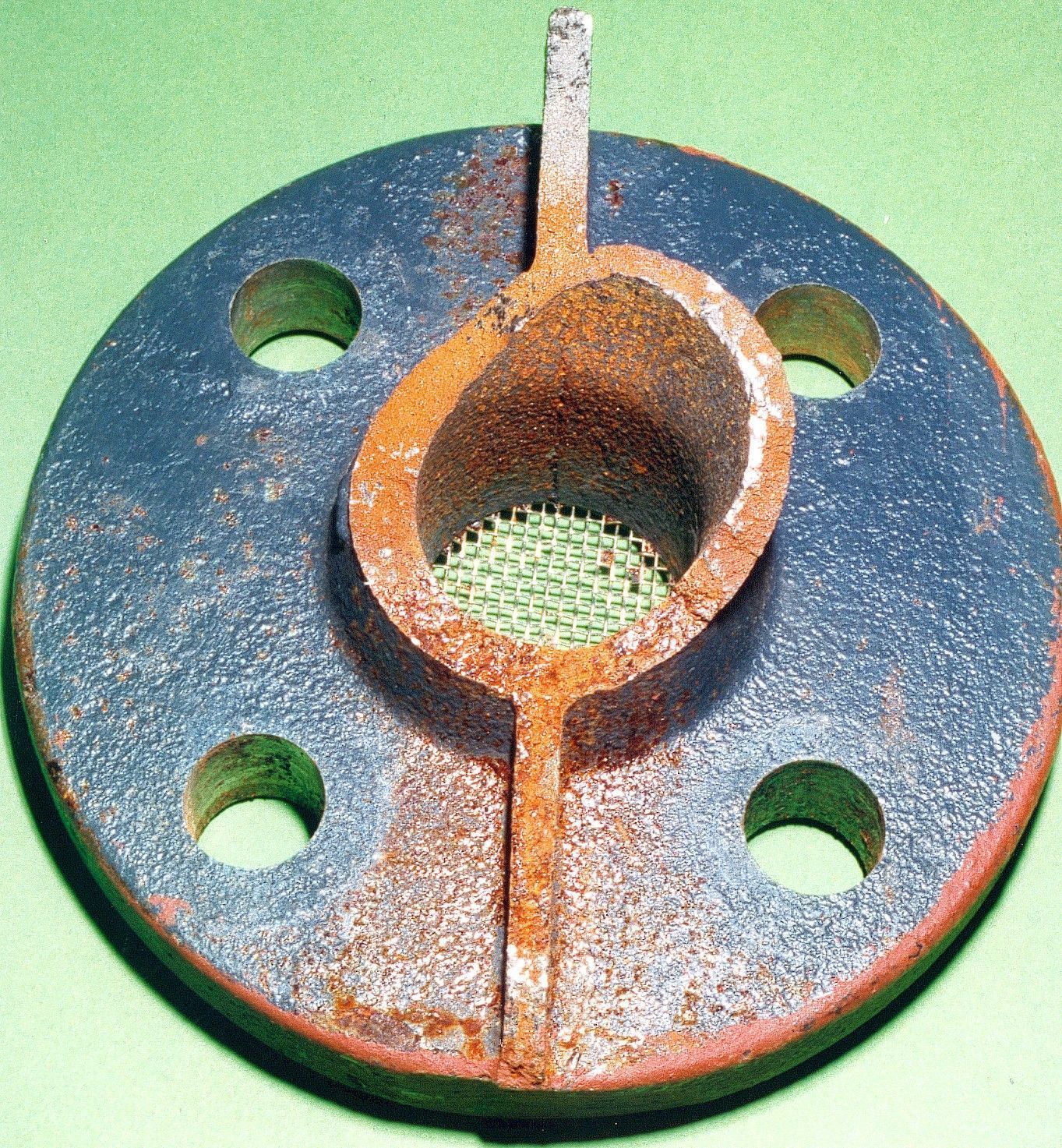

- Part, component and device failure analyses

- Chemical resistance

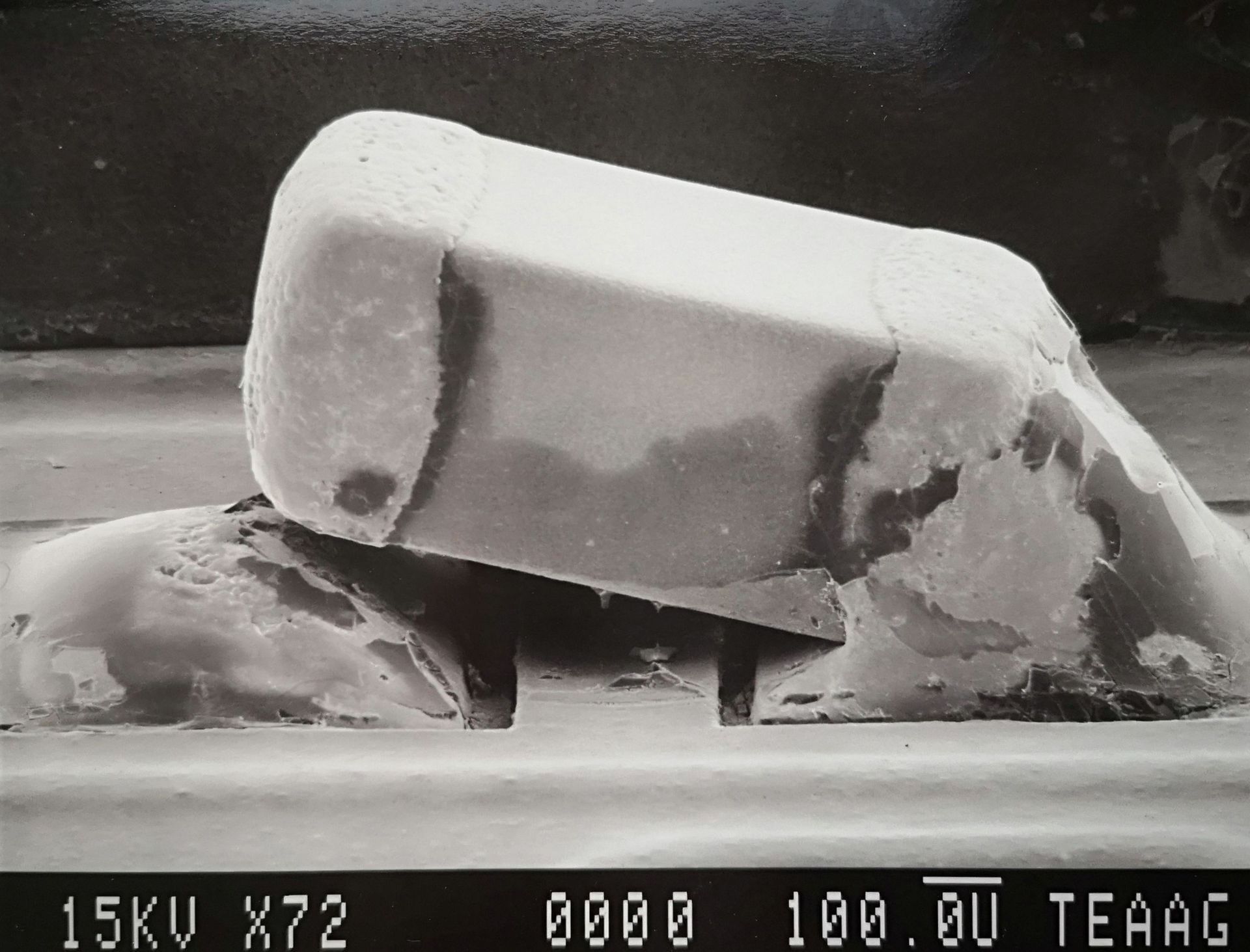

Damage analyses

- Fire cause analyses for devices and circuit boards

- Insulation failure and electrical breakdown analyses on parts, components and devices

- Part and component wear

- Corrosion, oxidation and surface changes on parts, components and devices

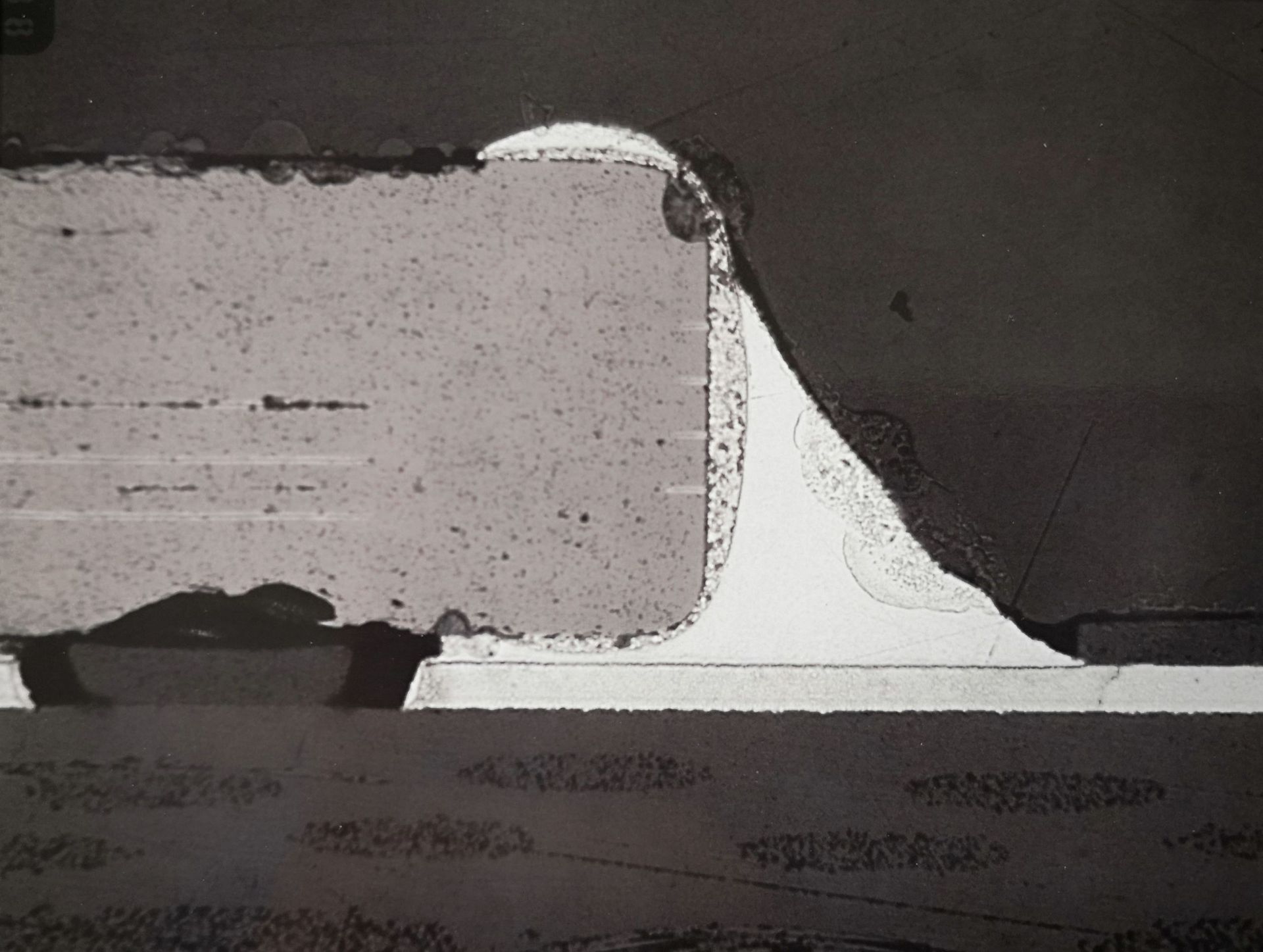

- Solder joint, screw coupling and crimp connection assessments

Identifying and eliminating the causes of failures is key to assuring a product’s safety and reliability.

Services and standards

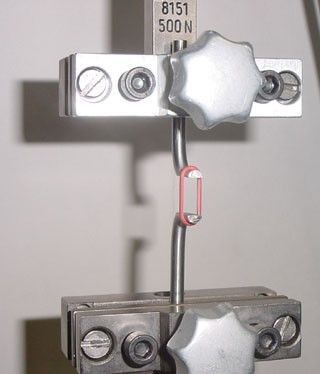

Tensile, pressure and hardness tests

- Universal testing machine,

single shaft, up to 100 kN

- Hardness testing HV, HB, HRC

- Shore hardness testing

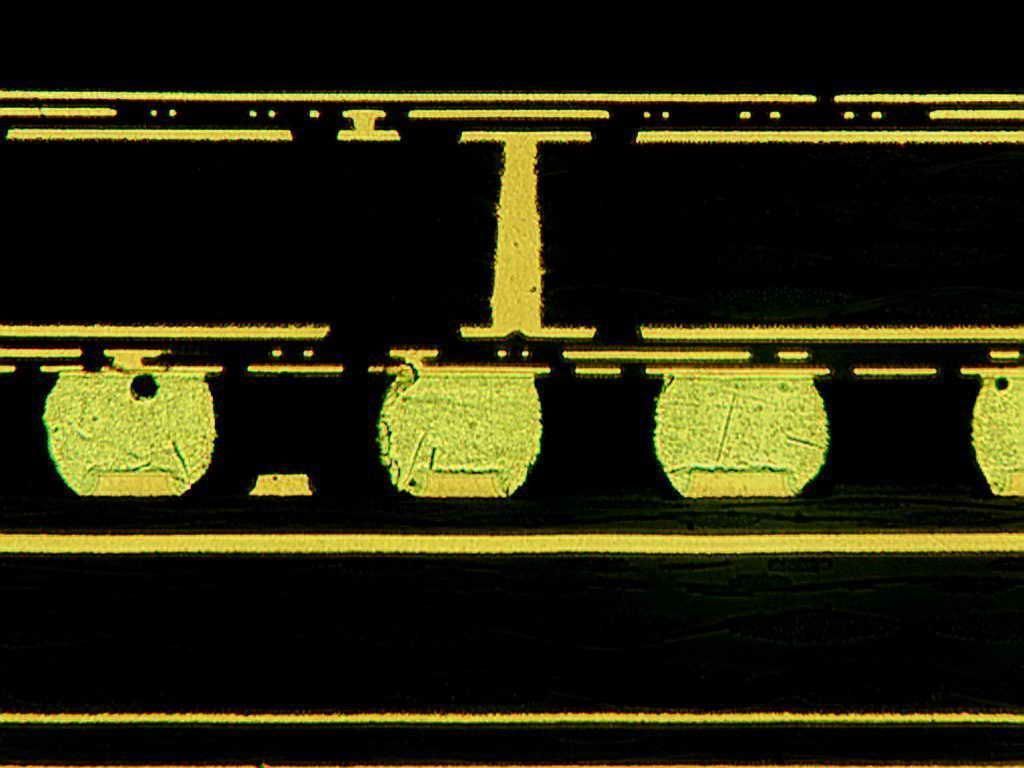

Metallography

- X-ray testing up to max.

100 kV

- Sample preparation

- Metallurgical microscope up to 1:1000

- Grain size determination

- Coat thickness measurement

- Structural analyses

Electrical connectors

- Resistance

- Insulation resistance

- Electric strength

- Electrical crimp performance

Chemical resistance

- Preliminary treatment

- Chemical application

- Inspection

EN 10002

ISO 527-1

ISO 6506-1, 6507-1, 6508-1

IPC-TM-650

MIL-STD-883

DIN EN ISO 1463

IPC-TM-650

IPC-A-600F

IPC-A-610D

ASTM E-3-1

MIL-STD-2118

MIL-STD-883

IEC/EN 60512-2-1

IEC/EN 60512-2-2

IEC/EN 60512-3-1

IEC/EN 60512-4-1

SAE/USCAR-21

ISO 16750-5

IEC/EN 60068-2-45

DIN/EN 2591-315

MIL-STD-883, RCTA DO-160