Engineering

Advice concerning relevant standards, statistical power for product qualification tests

Test engineering comprises the development of test strategies:

identifying what is being tested; test concepts:specifying how it is going to be tested; test procedures:

specifying how the test is going to be performed

Material engineering comprises assessing how changes to materials are going to affect their properties in terms of wear, corrosion and oxidation, as well as their electrical and thermal characteristics

Process engineering

comprises assessing the effects of any changes to the materials, e.g. flux, auxiliary materials such as solvents, the process temperature or the temperature

City skyline

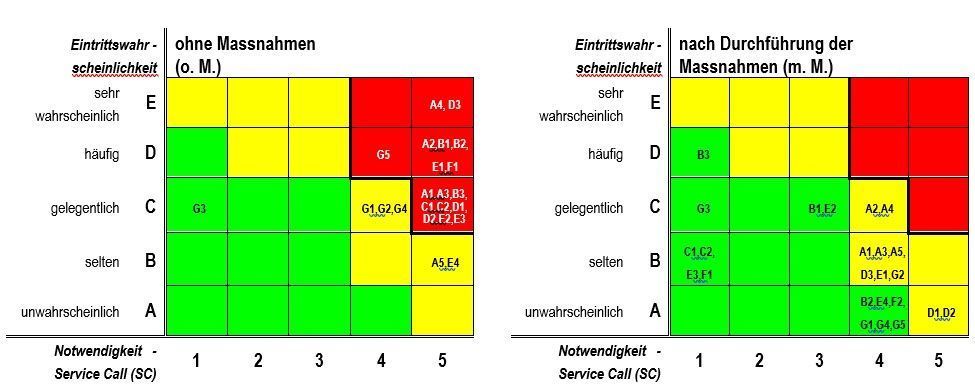

Product risk analysis

Identification of the product and failure risks and definition of measures for eliminating them

Identification of the risks associated with the functional units based on their design, risks that arise during manufacture, their transport, handling/maintenance, regarding choice of materials and their operating conditions

Creation of a risk matrix

Definition of measures for eliminating the risks

Proposal and implementation of targeted laboratory simulations and tests for verifying the risks and the measures for eliminating them

Use of the risk analysis for ongoing quality control